Via the material and the cross-sections of the rings we have set the tension required for our practical application case. ROLL-RING chain tensioners are available for roller chains in compliance with DIN 8187, ISO 05 B-1 to ISO 20 B-1 and with ANSI Standard B29,1, No. 35 to 100.

If the chain drives with these standardized chains meet the desired installation requirements with regard to the number of teeth on the sprockets, the center distance and the number of chain elements, then you can be sure that sufficient tensing and damping as well as the reliable positioning and reversibility will be given.

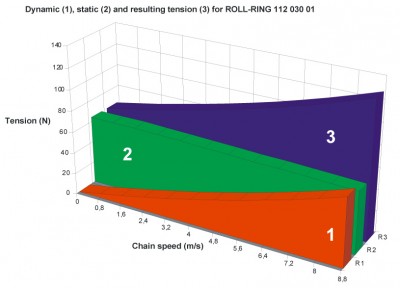

ROLL-RING chain tensioners prestress the chains with static tension from the resilience of the elastic ring with additional dynamic resilience from the speed-related damping of the material. The ROLL-RING chain tensioners provide as much tension as necessary at low chain speeds and have reserves of tensioning and damping capacity for higher chain speeds.